PRODUCTS DISPLAY

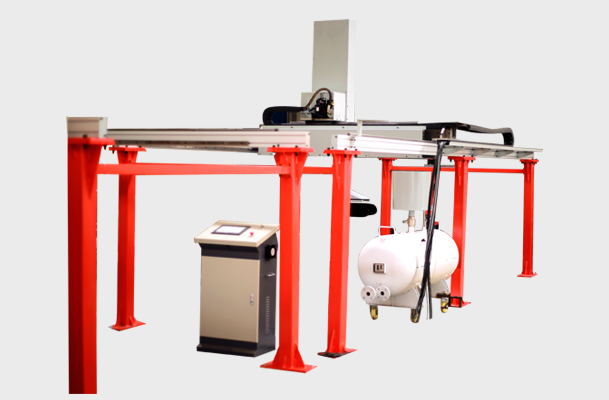

The oil brushing machine adopts a gantry type truss, including a longitudinal beam assembly, a cross beam assembly, a lifting shaft assembly and a column.

CONTACT US

The oil brushing machine adopts a gantry type truss, including a longitudinal beam assembly, a cross beam assembly, a lifting shaft assembly and a column. The longitudinal beam assembly is arranged on the column, and the truss is arranged above the mold box through a gantry type truss, so as to reduce the floor area. The movable cross beam can walk more smoothly on the truss by setting a plurality of columns, and the column is provided with a transverse rod and a longitudinal rod The mutual connection of the longitudinal rod and the directional rod plays an auxiliary supporting and reinforcing role. The two symmetrical longitudinal axis guides of the longitudinal axis assembly are connected by adjusting rods to adapt to different sizes of mold boxes.

Gantry truss type oil painting robot is a special equipment developed by us, which has the following characteristics: limited customer space, narrow oil painting area and unable to place conventional models:

1.The structure occupies less space, covers a large area, operates more stably, and is more convenient for installation and operation.

2.It can make good use of the existing traction mechanism of the aerated brick production line mold, saving a lot of transformation costs for Party A.

3.Accurate radar positioning, no stripping oil, uniform brushing, saving consumables, light and reasonable structure, convenient and fast maintenance.

4.The device has remote control of Internet of things, 24-hour monitoring of wireless camera head, automatic alarm in case of failure, and the manufacturer can eliminate the failure through short-range operation of computer, which greatly improves the after-sales efficiency.

5.4 or 5 sides of the mold can be selected for brushing, the oil surface is covered with 100%, and the gap does not leak, so as to ensure 100% demoulding.

6.The brushing time of each mold shall not exceed 100 seconds.

7.The equipment specifications can be customized according to the site requirements of your company.

Next:no more